California Slate Company, Inc.

General Information

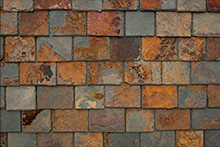

Slate Roofing

Slate roofing is one of the most distinguished building materials on the market, gracing many of the world’s most impressive buildings. Cathedrals, palaces, residential homes, and castles have utilized this long-lasting building material as a weathershield for centuries. In fact, it was the king of roofing materials at the turn of the twentieth century. United States slate consumption was at its highest in 1902.

“Slate Roofs: Design and Installation Manual”

In 2010, the National Slate Association published a detailed design and installation manual for slate roofs. We’ve obtained the right to share the document with our customers who request it. Click to email us for the publication and we’ll email you back a PDF version of the document.

Slate Myths

-

If slate comes from Vermont, it’s a high-quality material.

In reality, high-quality slate is found all over the globe…and so is low quality slate. While Vermont has some of the world’s best slate quarries not all Vermont quarries produce high-quality slate. It is very important to know the actual quarry that a particular slate shipment is coming from.

-

Domestic slate is always superior to imported slate.

The United States has some of the world’s best slate-producing quarries, but high quality slate is also mined in Spain, Wales, Canada, Brazil, and China. Different quarries produce different quality slate, irrespective of where they are located.

-

Chinese slate is intrinsically inferior.

Although the domestic slate industry in China goes back several hundred years, China is a relative newcomer to the international slate industry. In the early years, quality control in Chinese slate production was low. To some degree this is still a problem, but it has greatly improved. With the introduction of new technology, some very good slate has been shipped from this part of the world.

-

All Spanish black slate contains rust (pyrite) and is of inferior quality to black slate from North America.

This is simply not true.

The myth of Spain producing low quality slate does have interesting historical roots. Until very recently, almost all of the high-quality black slate from Spain was imported by France. France and Spain are geographic neighbors, and France was Spain’s dominant trading partner for slate. Since France has one of the strictest slate standards in the world, there wasn’t much high-quality black slate left for export to other countries. What was exported was the lower-grade slate which didn’t match the French standards. And thus arose the poor reputation of the Spanish slate industry.

This all changed when the significant downturn in the French economy freed up high-quality Spanish black slate for export to other nations. We are now fortunate to receive some amazing black Spanish slate here in the United States.

-

Slate that ‘weathers’ or changes color over time is of lower quality than slate that keeps its original color.

While “unfading” slate maintains its color for most of its lifetime, “weathering” slate weathers by slowly changing color over time. This happens when bits of organic material trapped in the slate are exposed to atmosphere. Thus, green weathering slate might turn browner in color over many years.

Slate quality, which relates to its durability as a roofing material, has to do with its low absorption of water, its fracture strength, and its resistance to corrosion. The presence or absence of organic matter doesn’t affect those factors – so the fact that weathering slate changes colors is not an indication of lower quality. Some people want the slate to change color over time and others do not. It’s up to the homeowner and the architect to make a decision as to whether the changing appearance of the material is a desired feature of the roof slate.

True Black Slate

In order to qualify as a “True Black” slate, it must fulfill two criteria:

- Slate must be “black,” not gray, or dark gray, or charcoal gray.

- Slate must be “unfading” or “non-weathering.” It must maintain its original black color over the years without changing.

Slate fulfilling these criteria has only been found in Spain. Other countries produce black slates, but we have not yet found any that satisfactorily meet the second criteria.

In general, we’ve found that black slates from countries other than Spain are undesirable.

| Weight | Durability | ||

|---|---|---|---|

| kg. per meter2 | lbs. per square | Years | |

| Natural Slate 7 mm (¼″ thick) | 48 | 950 | 120 |

| Natural Slate 5 mm (⅕″ thick) | 33 | 650 | 100 |

| SLATE2 | 28 | 550 | 120 |

| Clay Tiles | 60 | 1,250 | 40 |

| Concrete Tiles | 55 | 1,100 | 30 |

| Fibre Cement | 25 | 500 | 25 |

| Asphalt Shingle | 12 | 250 | 20 |